Category - pumps

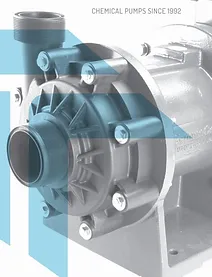

HTP – magnetic driven centrifugal pump

Sealless thermoplastic solutions for highly corrosive and toxic liquids

- Material selection: Polypropylene (PP) or PVDF

- Capacity: Up to 138 m³/h

- Max lifting height (H): 48 m (metric liquid column)

- Viscosity limits: Up to 2000 cP (Max 200 cSt)

- Temperature range: PP up to 70°C | PVDF up to 90°C

- System pressure: 6 bar at 20°C

- O-rings: High-durability EPDM or VITON

Industries and applications

Mag-drive centrifugal pumps series HTM PP/PVDF are made of thermoplastic materials (polypropylene and PVDF) and are suitable for highly corrosive liquids. Thanks to the innovative mag-drive system, pumps model HTM PP/PVDF reduce the risk of losses and maintenance costs. The transmission of movement is through magnetic joints without the use of mechanical seals. This guarantees maximum safety and efficiency.

The pumped liquid must be clean and free of solids in suspension.

Design of magnetic drive centrifugal pumps

Magnetic pumps have a special sealless design suitable for pumping corrosive and hazardous liquids thanks to their high chemical resistance and the absence of leakage and discharge. The structure is very simple so that the pump requires a very reduced maintenance with subsequent savings in terms of repair and spare parts costs over the life of the pump. The external magnet placed on the drive shaft transmits the movement to the internal magnet connected to the impeller which rotates and moves the liquid through the pump.

Reliable protection for toxic and harmful liquids

The HTM series is the ideal choice for pumping toxic, harmful, and carcinogenic liquids. The sealless design guarantees that no hazardous vapors or fluids escape the system.

Requirement: To ensure optimal performance and longevity, the pumped liquid must be clean and free of solids in suspension.