Catagory - pumps

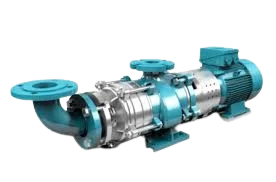

Multistage centrifugal and self-priming pumps

High-pressure solutions for complex media and industrial applications

- Capacity (Q): 2 to 900 m³/h

- Delivery head (H): Up to 400 m

- Max pressure (p): 40 bar

Side channel pump technology

A side channel pump represents a high-performance cross between a positive displacement pump and a centrifugal pump. Originally designed for pumping media containing mixed liquid, air, and gas, it is now an essential component in diverse industrial systems.

Multistage centrifugal pumps

Side Channel Pump: A self-priming hybrid design that efficiently handles mixtures of liquid, air, and gas.

Key Characteristics: Features a steep curve (Q/H) for pressure regulation, very low NPSH requirements, and gas transport capability without dry-running damage.

Design: Horizontal, radial-split casing, multistage between-bearing pump with closed impellers.

Applications: High-pressure handling for boiler feed, reverse osmosis, desalination, and fire protection.

Performance: Capacity up to 900 m³/h, head up to 400 m, and pressure up to 40 bar.

Operating Limits: Temperature range from -25°C to +140°C; available with ATEX Zone 1 & 2 certification.

Multistage self-priming pumps

Side Channel Pump: A self-priming hybrid design that combines positive displacement and centrifugal technology to handle liquid, air, and gas mixtures.

Key Characteristics: Features a steep (Q/H) curve for pressure regulation, very low NPSH requirements, and gas transport capability without dry-running damage.

Design: Horizontal, radial-split casing, multistage between-bearing pump with closed impellers.

Applications: High-pressure handling for boiler feed water, reverse osmosis, desalination, and fire protection systems.

Performance Range: Capacity from 2 to 900 m³/h, head up to 400 m, and pressure up to 40 bar.

Specifications: Operating temperatures from -25°C to +140°C; available with ATEX Zone 1 and 2 certifications and 60Hz options.