Catagory - pumps

Eccentric disc pumps (JE series)

High-performance jump pumps for shear-sensitive and viscous fluids

Capacity: Models available up to 96 m³/h

Temperature range: Reliable transfer from -5°C to +250°C

Maintenance: Innovative front seal disassembly without disconnecting pipes

Side channel pump technology

A side channel pump represents a high-performance cross between a positive displacement pump and a centrifugal pump. Originally designed for pumping media containing mixed liquid, air, and gas, it is now an essential component in diverse industrial systems.

Eccentric disc pumpgal pumps

Operating principle: A shaft drives a piston inside a cylinder. The eccentric movement creates two pumping chambers

that allow the transfer of fluid from the suction to the discharge port.

- Pump type: Self-priming pump with full reversibility and dry-running capabilities.

- Performance: Features a very low shear rate and strong suction/compression force for complete pipe emptying.

- Efficiency: Maintains constant flow rate and pressure performance over time.

- Maintenance: Reduced downtime via an innovative front seal disassembly system that doesn't require disconnecting pipes or the gearmotor.

- Construction: Available in ductile iron, stainless cast iron, and 316L stainless steel with customizable flanges.

- Technical specs: Includes an integrated double bypass, flow rates up to 96 m³/h (ATEX models up to 16 m³/h), and temperatures from -5°C to +250°C.

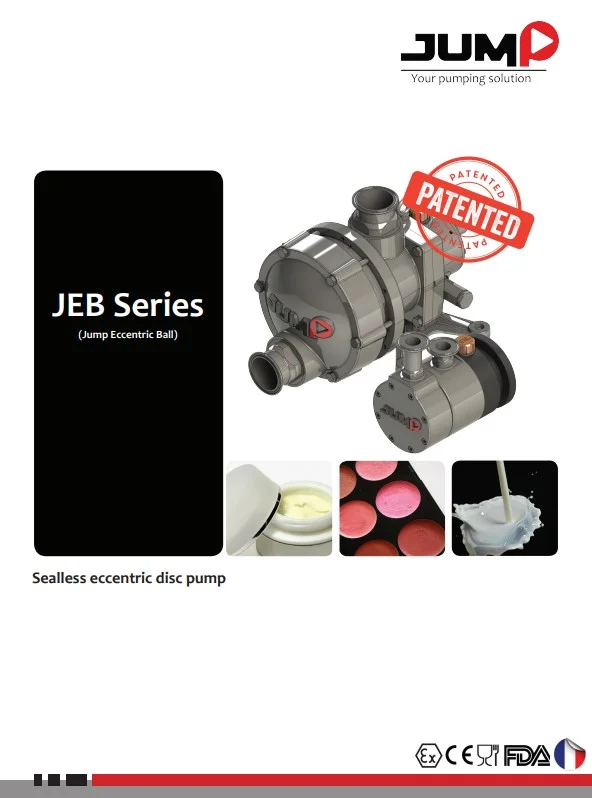

Sealless eccentric disc pump

Operating principle: A shaft drives a piston inside a cylinder. The eccentric movement creates two pump chambers

that allow the transfer of liquid from the suction to the discharge port. The sealing system is made by a set of

ball joints coated with an elastomer sleeve to avoid retention zones in the pump.

- Pump type: Self priming pump with dry-running capabilities.

- Performance: Features a very low shear rate and strong suction/compression force for complete pipe emptying.

- Design: Hygienic design with no storage zones to prevent fluid stagnation.

- Maintenance: Engineered for reduced maintenance time and easy accessibility.

- Construction: Available in ductile iron and 316L stainless steel with customizable flanges.

- Sanitation: CIP (Clean-In-Place) and SIP (Sterilization in place) simplified up to 10 bar.

- Technical specs: Flow rate up to 42 m³/h (ATEX models up to 3 m³/h) and transfer temperatures from -5°C to +125°C.