Category - pumper

Lobe pumps – industry, sewage & biogas

High-performance positive displacement pumps featuring perfectly synchronized high-precision rotors. Designed for maximum availability and easy maintenance in the most demanding environments.

Capacities up to 154 m³/h.

Pressures up to 7 bar.

Self-priming & dry-running resistant.

Industries and applications

The operating principle of a lobe pump is based on the precise movement of the rotors, which in turn depends on the perfectly regulated synchronization of a corresponding set of high-precision gears.

The result is a positive displacement volumetric pump with exceptional performance. The concept of the sanitary version that concerns us here is designed to ensure exceptional reliable performance with a focus on easy maintenance. The synchronization of precision wheels eliminates any contact with high precision rotors, there is absolutely no change of metal components touching

IQ112 Series

The ultimate solution for rapid maintenance and cost-effective service. Engineered for easy handling of difficult media and contaminated fluids.

Typical applications: Primary sludge, contaminated used oil, and media containing coarse particles.

Capacity:

Up to 78 m³/h | Pressure: Up to 7 bar.

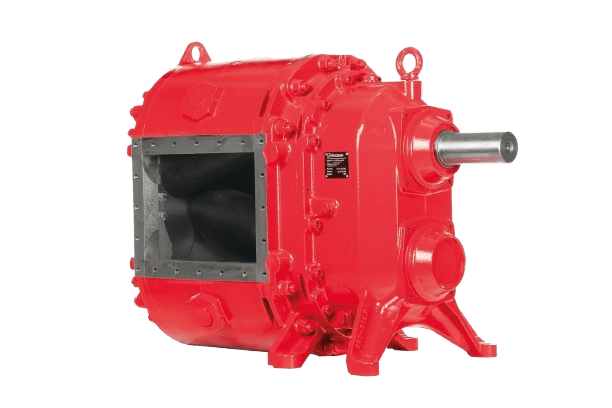

IQ152 Series

The powerful choice for high-capacity requirements. This series minimizes downtime in industrial settings through a robust, reduced-maintenance design.

Typical applications:

Large-scale sewage treatment, wastewater plants, and heavy industrial applications.

Capacity: Up to 154 m³/h | Pressure: Up to 7 bar.

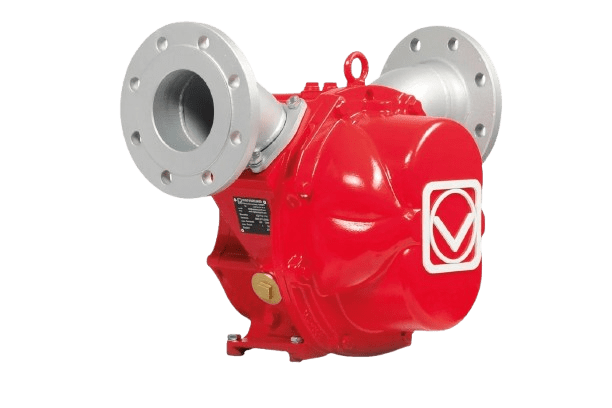

VX Series

A versatile and compact range of rotary lobe pumps featuring a high-efficiency design and an extensive selection of customizable features.

Typical applications:

Biogas plants, mineral oil products, and general industrial pumping tasks.

Features: Reversible pumping direction, dry-run protection, and high resistance to foreign bodies.