Category - pumper

Internal eccentric gear pump

Based on the “gear-in-a-gear” principle with only two moving parts, ensuring reliable and efficient operation for all positive displacement needs.

- Capacity: 0.48 – 350 m³/h

- Max Pressure: 8 – 20 bar

- Temperature: 200 – 180°C

Viscosity: 100 – 250,000 SSU

Industries and applications

The pump is delivered with a “gear-in-a-gear” principle and has only two moving parts.

That is the secret to the reliable and efficient operation of all positive displacement pumps. The positive displacement of fluid is achieved by completely filling the spaces between the rotor teeth and the space between the gear. The only limiting factor for peak performance with these pumps, as with all rotary pumps, is that the fluid being pumped must be relatively clean.

With each revolution of the pump shaft, a certain amount of liquid enters the pump through the suction part at the inlet. The incoming liquid fills the spaces between the rotor and the free space. The crescent on the pump head divides the flow of liquid as it moves smoothly towards the outlet. The idler gear, which carries the liquid between the teeth and the inner surface of the crescent, is connected to the pump housing. On the other hand, the rotor gear, which is rotated directly with the pump shaft, delivers liquid between the gear and the crescent.

V 100-2 SPHTR

Specifically designed for temperature-sensitive fluids, this model features an integral heating jacket to maintain constant liquid temperature and prevent fluid solidification during transfer.

Typical applications: Bitumen, tar, asphalt, chocolate, molasses, and heavy fuel oils that require constant heat to remain flowable.

Capacity:

Up to 350 m³/h (V-Series Max range).

BMF-BCF (Monoblock gear pumps)

A compact, space-saving monoblock gear pump for direct coupling, perfect for integrated industrial systems.

Typical applications:

Machine lubrication, small chemical dosing, and coolant circulation.

Capacity: 2 – 70 L/min.

Max pressure: 12 bar

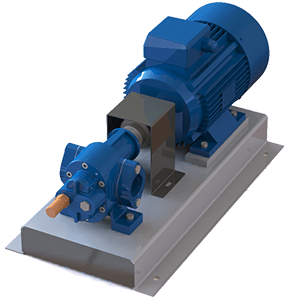

MBM B pumps mounted on skid frame

High-volume "B" series pump mounted on a heavy-duty skid frame for maximum stability during high-pressure transfers.

Typical applications: Bulk petroleum transfer, diesel, crude oil, and large-scale soap production.

Capacity: 5 – 800 L/min.

Max pressure: 12 bar

The wide range of applications includes:

Chemicals & pharma: Solvents, acids, bases, alcohols, and isocyanates.

Petroleum & energy: Gasoline, diesel, fuel oils, and crude oil.

Food & beverage: Chocolate, molasses, vegetable oils, and glucose.

Heavy industry: Adhesives, epoxy resins, bitumen, tar, and asphalt.

Hygiene: Surfactants, liquid detergents, soaps, and additives.

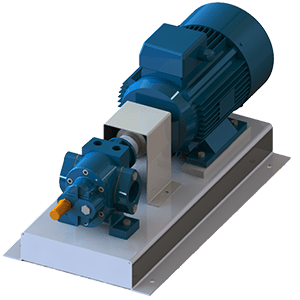

MBMC BC Pumps mounted on skid frame

Specialized "BC" configuration on a skid frame, optimized for medium-range flows requiring high consistency.

Typical applications: Adhesives, epoxy resins, surfactants, and liquid detergents.

Capacity:

5 – 400 L/min.

Max pressure: 12 bar

Viscosity: 1-100cSt

IF low viscosity gear pumps

Engineered with tight tolerances to handle thin liquids efficiently without the performance loss seen in standard pumps.

Typical applications:

Solvents, alcohols, gasoline, and light additives.

Capacity: 5 – 80 L/min.

Max pressure: 25 bar

Viscosity: 1-1000 cSt