Catagory - pumps

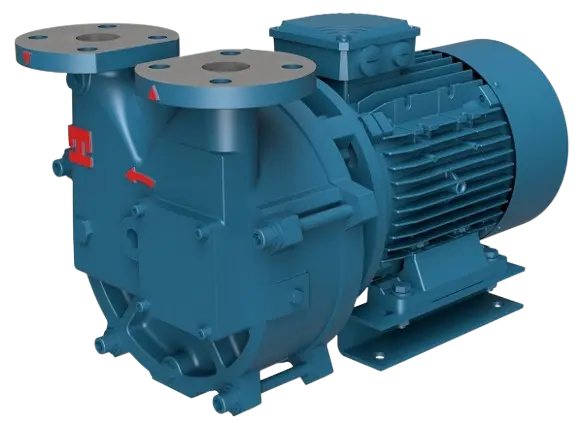

Liquid ring vacuum pumps

The pumps are mostly used in drying, evaporation, evacuation and removal of gases.

Impeller: Multi-stage

Pump design: horizontal

Skid/frame

Area of use: Evaporation, drying, removal of gases.

Industry: Chemical, petrochemical, food, textile

Areas of application

Liquid ring vacuum pumps operate on the displacement principle for transporting air, gas and steam

Transportation: The air is sealed and compressed by the rotating liquid ring. Pump design provides low load

Efficiency: The power is measured in KW at the shaft with dry air at 20 °C, water (service fluid) at 15 °C and a barometer of 1013 mbar. The efficiency may vary depending on the environment.

2-stage liquid ring vacuum pumps (TRH)

- High pressure: Designed for high-pressure industrial applications.

- Capacity: High-volume output up to 3500 m³/h.

- Suction Pressure: Capable of reaching 33 mbar.

1-stage liquid ring vacuum pumps (TRS)

- Pressure Range: Low and medium pressure.

- Vacuum Range: Low and medium vacuum.

- Capacity: High-volume output up to 3500 m³/h.

- Suction Pressure: Capable of reaching 150 mbar.

1-stage liquid ring vacuum pumps (TRV)

Features a retracted, backswept impeller that creates a vortex in front of the impeller to protect the housing.

Advantage: Discharges 80% of solids without contact, making it ideal for long fibers and abrasive slurries.

1-stage liquid ring vacuum in monoblock

- Vacuum Range: Low, medium, and high vacuum.

- Capacity: High-volume output up to 300 m³/h.

- Suction Pressure: Capable of reaching 33 mbar.

1-stage liquid ring vacuum pump and compressor

- Vacuum Range: Low, medium, and high vacuum.

- Capacity: High-volume output up to 600 m³/h.

- Suction Pressure: Capable of reaching 33 mbar.