Category - pumps

Magnetically driven vane pumps

Sealless positive displacement technology for zero-leakage fluid transfer

- Operating principle: Self-priming positive displacement

- Flow characteristic: Constant flow at varying pressures

- Safety: Integrated relief valve and hermetically sealed hydraulic chamber

Industries and applications

A vane pump is a self-priming positive displacement pump that provides constant flow at varying pressures. A vane pump operates via a motor connected via a gearbox, with a typical maximum speed of 900 rpm. The pump is equipped with a relief valve to prevent the pump from building up to a pressure that could damage the pump.

Vane pumps are typically used for viscous liquids such as lubricants such as oils, petroleum, diesel, animal oils/blood, solvents and fuel oil

In a sealless magnetic drive pump, the external magnet connected directly to the motor shaft transmits the torque to the internal magnet. The magnetic field created produces a rotation without physical contact between the parts and the rotor spins. The vanes inside the rotor slide in and out of the seat, and they move the fluid. The rear cover is placed between the two magnetic joints and hermetically seals the hydraulic part from the motor.

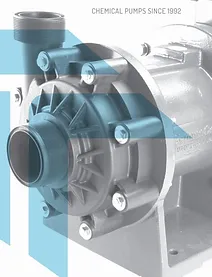

HTP – Magnetically driven vane pump

- Material: AISI 316 Stainless Steel.

- Capacity: Up to 2000 lpm.

- Max Pressure: 13 bar.

- Viscosity: Up to 2000 cP.

- System Pressure: 25 bar.

- Temperature: Up to 200 °C (Standard performance at 20 °C).

- Sealing: EPDM/VITON O-rings.

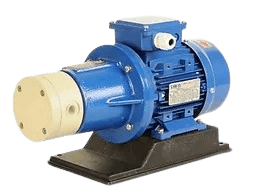

HPP/HPF – Magnetically driven vane pump

- Material: PP (Polypropylene) or PVDF.

- Capacity: Up to 1000 lpm.

- Max Pressure: 5 bar.

- Viscosity: Up to 2000 cP.

- Working Pressure: Up to 34.5 bar.

- Temperature Limits: PP up to 70 °C | PVDF up to 90 °C.

- System Pressure: 8 bar.

- Rotor Material: PVDF.